PF-1320 Series Primary Impact Crusher With Great Advantages

| Price: | 1.0~100000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Production Capacity:

69 Set/Sets per Month

Delivery Date:

within 15 working days afte...

Type:

Crusher

Condition:

New

Discharging size(mm):

Max.5

weight(t):

26

warranty:

1 year

Packing:

export standard or nude pac...

Application:

Coal

Brand Name:

zhongcheng

Max.feeding size(mm):

120

power(kw):

180

quality guaranty:

ISO&CE

service:

technical guidance

1.China high-efficient fine impact crusher

2.Versatile and efficient

3.Low energy consumption

4.Reliable operation

5.ISO

PF-1320 Series Primary Impact Crusher With Great Advantages

1.Usage and Application of Impact Crusher:

Impact crusher is used in mineral dressing, chemical industry, cement, building materials, fire-proof materials, ceramics, glass and other industries, for crushing medium hardness ore, such as limestone, quicklime, slag, calcium salt, clay mine, building materials, coke, coal and other materials which with the compression strength up to 350Mpa

2.Features of impact crusher:

(1) can be crushed for hard rocks

(2) connection with locking sleeve assembly

(3) the blow bar with high chrome

(4) hydraulic or hand opening

(5) impact plate with special shape

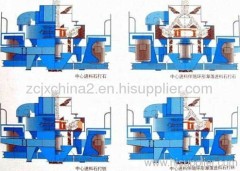

3. Working Principle of impact crusher:

When the impact crusher works, the motor drives the rotor rotate of the impact crusher with high speed, on the rotor where installed the hammers. When the materials get into the area which the hammers effect, under the impact function of the hammer at a high speed, the materials are thrown to the impact device above the rotor continuously. And then the materials are rebounded from the impact liner to the area where the hammers effects for being recrushed. The materials from large to small all to be crushed at the impact chamber repeatedly. The process won't stop till the material are crushed to the required size and then discharged from outlet of the impact crusher.

4.Main Technical Paraneters of impact crusher:

Type | Spec. (mm) | Feeding opening(mm) | Max. feeding size(mm) | Production capacity(t/h) | Power(kW) | Weight(t) |

PF0607 | 644X740 | 320X770 | 100 | 10-20 | 30 | 5.6 |

PF1007 | 1000×700 | 400×730 | 300 | 30-70 | 37-55 | 9.5 |

PF1010 | 1000×1050 | 400×1080 | 350 | 50-95 | 55-75 | 14 |

PF1210 | 1250×1050 | 400×1080 | 350 | 70-140 | 110-132 | 17 |

PF1214 | 1250×1400 | 400×1430 | 350 | 130-180 | 132-160 | 22 |

PF1315 | 1320×1500 | 860×1520 | 500 | 160-250 | 180-260 | 26 |

PF1320 | 1320×2000 | 860×2030 | 500 | 300-350 | 300-375 | 30 |

Related Search

Impact Crusher

Zenith Impact Crusher

Shaft Impact Crusher

Impact Crusher Machine

Vertical Impact Crusher

Vertical Shaft Impact Crusher

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

henan zhongcheng Co.,Ltd [China (Mainland)]

Business Type:Manufacturer, Trading Company

City: Zhengzhou

Province/State: Henan

Country/Region: China (Mainland)

You May Like:

Product (300)

- vibrating feeder (10)

- shaving bed (20)

- rotary dryer (30)

- Block Molding Machine (15)

- spiral chute (25)

- magnetic separator (14)

- classifier (17)

- floatation machine (19)

- belt conveyor (20)

- ball mill (9)

- crusher (121)

.gif)