Excellent fine impact crusher price with high productivity and competitive price

| Price: | 1.0~100000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Production Capacity:

78 Set/Sets per Month

Delivery Date:

within 15 working days afte...

Type:

Crusher

Condition:

New

Discharging size(mm):

Max.5

weight(t):

26

warranty:

1 year

Packing:

export standard or nude pac...

Application:

Coal

Brand Name:

zhongcheng

Max.feeding size(mm):

120

power(kw):

180

quality guaranty:

ISO&CE

service:

technical guidance

1.China high-efficient fine impact crusher

2.Versatile and efficient

3.Low energy consumption

4.Reliable operation

5.ISO

Excellent fine impact crusher price with high productivity and competitive price

1. Introduction of fine impact crusher:

Our company's high-fine crusher, according to other crushers' works principle and the specific use of the user feedback, integrated the advantages of the design of new high sand equipment (crushing machine). The typical use is to meet the current artificial sand industry is rod mill-type sand making machine, impact-type sand making machine, sand making straight-through alternative. This product has: a small particle size, particle type uniform, large capacity, hammer, long life, supporting power smaller, three broken for the second crushing, process simplification, simple structure, easy maintenance, smooth operation and so on. Investment in equipment than traditional techniques and equipment similar size 35% -50% higher than the same size traditional output efficiency of 35% -50% technical equipment (for example limestone: a refined grain size ≤ 5mm more than 85%). Long-run maintenance costs than traditional techniques and equipment similar size 35% -50% are widely used mechanism to aggregate, cement, refractory and metallurgical industries.

2. Application of fine Impact Crushers:

Fine Impact Crusher can crush many kinds of large, medium, small materials such as rock or stone whose side length is less than 500mm, and compression resistance should not be more than 350Mpa. And The impact crusher (impactor) is widely used in hydroelectricity, highway, artificial rock, stone and sand, building material, etc.

3. The main features of fine impact crushers:

1) Connected with locking sleeve assembly

2) Final product with cubical shape

3) The blow bar with high chrome

4) Easy maintenance. Hydraulic or hand opening

5) Easy maintenance and reliable operation

6) High reduction ratio and crushing efficiency

7) Impact plate with a special shape.

2) Final product with cubical shape

3) The blow bar with high chrome

4) Easy maintenance. Hydraulic or hand opening

5) Easy maintenance and reliable operation

6) High reduction ratio and crushing efficiency

7) Impact plate with a special shape.

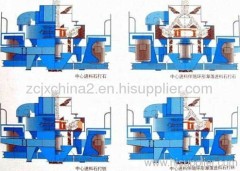

structural drawings of fine impact crusher

4. Main technical parameters of fine impact crusher:

pxj fine crushe | rotor width (mm) | rotor width (mm) | rotor width (mm) | rotor width(mm) | rotor width (mm) | rotor width (mm) | rotor width(mm) | rotor width (mm) | rotor width(mm) |

type | 800*400 | 800*600 | 800*800 | 1010*400 | 1200*1000 | 1200*1200 | 1400*1400 | 1600*1600 | 1800*1800 |

input size(mm) | 400*185 | 500*250 | 550*330 | 1000*350 | 1200*400 | 1200*450 | 1500*500 | 1600*550 | 1800*800 |

input size(mm) | <120 | <180 | <180 | <180 | <180 | <180 | <190 | <190 | <190 |

output size(mm) | <5 | <5 | <5 | <5 | <5 | <5 | <5 | <5 | <5 |

The width of the discharge gap adjustment | 5-20 | 5-20 | 5-20 | 5-20 | 5-20 | 5-20 | 5-20 | 5-20 | 5-20 |

Cement clinker(T/H) | 20-30 | 35-40 | 35-45 | 45-55 | 80-110 | 100-110 | 100-150 | 170-210 | 250-270 |

limestone(T/H) | 35-45 | 45-55 | 55-65 | 65-75 | 50-100 | 90-100 | 100-150 | 190-250 | 280-310 |

power(KW) | 37-45 | 45-55 | 45-55 | 55-75 | 100-110 | 100-132 | 160 | 250 | 315 |

Service Promise

Before-sale services: We guide customers to choose the best applicable device type and provide the advanced, energy-saving and practical technological process, and also we are responsible for the site planning and design.

On-sale services:products must be inspected strictly before sell, customers are invited to simulate and test machine on-the-spot and raise objections. We will organize delivery according to the clauses stipulated in the contract.

After-sale services:Our Company will send professional engineers to guide installation, debugging and training operators until customers are fully satisfied. Moreover, we can design and manufacture products according to customers' specific requirement.

Related Search

Price Tag

Price Computing

Price Scale

Electronic Price Scale

Electronic Price Computing Scale

Price Computing Scale

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

henan zhongcheng Co.,Ltd [China (Mainland)]

Business Type:Manufacturer, Trading Company

City: Zhengzhou

Province/State: Henan

Country/Region: China (Mainland)

You May Like:

Product (300)

- vibrating feeder (10)

- shaving bed (20)

- rotary dryer (30)

- Block Molding Machine (15)

- spiral chute (25)

- magnetic separator (14)

- classifier (17)

- floatation machine (19)

- belt conveyor (20)

- ball mill (9)

- crusher (121)

.gif)